|

The ship structure is made of riveted puddle iron. It is an intermediate step in the ferrous metals evolution. Before, the construction world was using cast iron which is fragile and not suitable to riveting. Later, puddle iron was abandoned after the invention of the carbon steel which is much more powerful and easier to work. Puddle iron was mainly used between 1840 and 1900.

The big maintenance deal is to protect the hull against rust by painting it following an adapted process. And that this process must not be repeated every two years !…

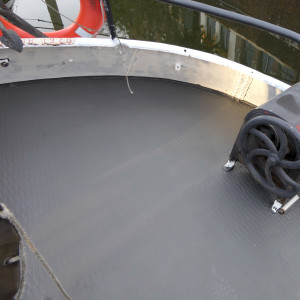

My objective was to (try to) use a modern process based on a two component epoxy primer (two layers should be the best) and a two component paint, typically polyurethane based (two layers). Finally the final paint was a product called DD Lack. Rust removing plus four layers of paint means minimum a 5 days working cycle in a dry and not too cold environment (minimum 15 °)… in a country where humidity and rain are often at the rendez-vous. |

Removing rust and applying a rust converter.

Removing rust and applying a rust converter. Painting the epoxy primer.

Painting the epoxy primer. Final paint layers

Final paint layers Painting the epoxy primer.

Painting the epoxy primer. Preparation.

Preparation.